Tralytex Joint Stock Company, formerly known as Thai Binh Jute Carpet Yarn Factory, was founded in 2005 and is now one of the most reputable yarn manufacturers in Vietnam. The company currently operates four spinning factories, providing stable employment for nearly 700 workers.

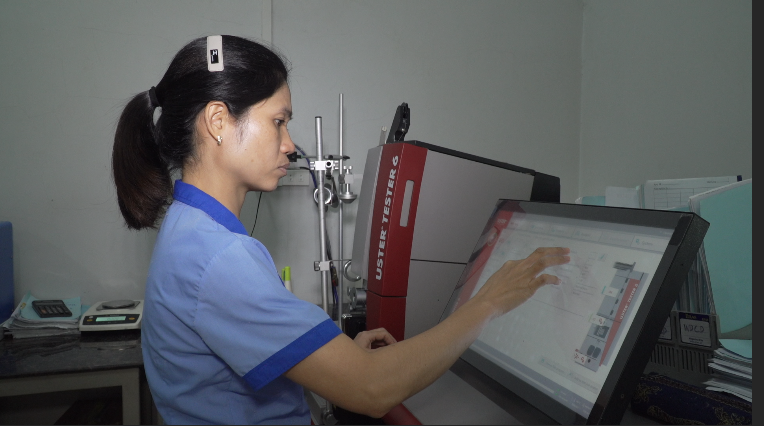

Entering the Industry 4.0 era, Tralytex has proactively invested in technology upgrades, integrating automated machinery from renowned brands such as Rieter, Trutzschler, Murata, Jingwei, and Jossi. These investments aim to save energy, enhance product quality, increase productivity, lower production costs, and ultimately, strengthen competitiveness in the market while also improving working conditions for employees.

Tralytex Invests in Energy-Saving Technologies.

Mr. Bui Ngoc Long - Deputy General Director of Tralytex said: "The nature of yarn spinning is hot and noisy, electricity accounts for a large cost in the total production cost, so the Company pays special attention to saving electricity. Tralytex understands that saving electricity is beneficial to itself, thereby improving production and business efficiency, increasing competitiveness in the market".

Tralytex has boldly invested in a series of energy-saving measures, achieving significant results. Specifically, 100% replacement of fluorescent lights with energy-efficient LED bulbs; Installation of power factor correction systems (cosφ compensation) at all central substations and large electrical loads; Installing inverters for 100% of asynchronous motors.

In addition, the Company also researches and limits production during peak hours..., thereby reducing electricity costs.

Tralytex has replaced 100% of fluorescent bulbs with energy-saving LED bulbs.

Discussing highly effective energy-saving initiatives, Mr. Long highlighted Tralytex’s adoption of the ESCO model. This approach allows the company to use clean energy without upfront investment, thereby reducing reliance on the national power grid and lowering greenhouse gas emissions.

"Currently, three of Tralytex’s factories have installed rooftop solar power systems with a total capacity of approximately 3 MWp. This solution not only reduces electricity costs and emissions but also allows Tralytex to obtain clean energy certification, facilitating access to international customers," Mr. Long emphasized.

Rooftop solar power system with a capacity of 3 MWp.

By investing in technological innovation and implementing energy-saving measures, Tralytex has significantly enhanced product competitiveness in the global market.

| According to statistics from the Ministry of Industry and Trade, the industrial sector accounts for more than 50% of the country’s total energy consumption, with energy-saving potential ranging from 20% to 30%. Therefore, expanding energy-saving initiatives across manufacturing enterprises not only helps businesses reduce investment and operating costs but also plays a crucial role in Vietnam’s economic and social development. |

Duc Do