Thang Nam Forestry Joint Stock Company (a member of TH Group) was established in January 2010. It specializes in the production of MDF fiberboard and laminated wood panels. The company's products are equipped with modern technology, equipment, and management processes and meet all customer requirements and the most stringent standards.

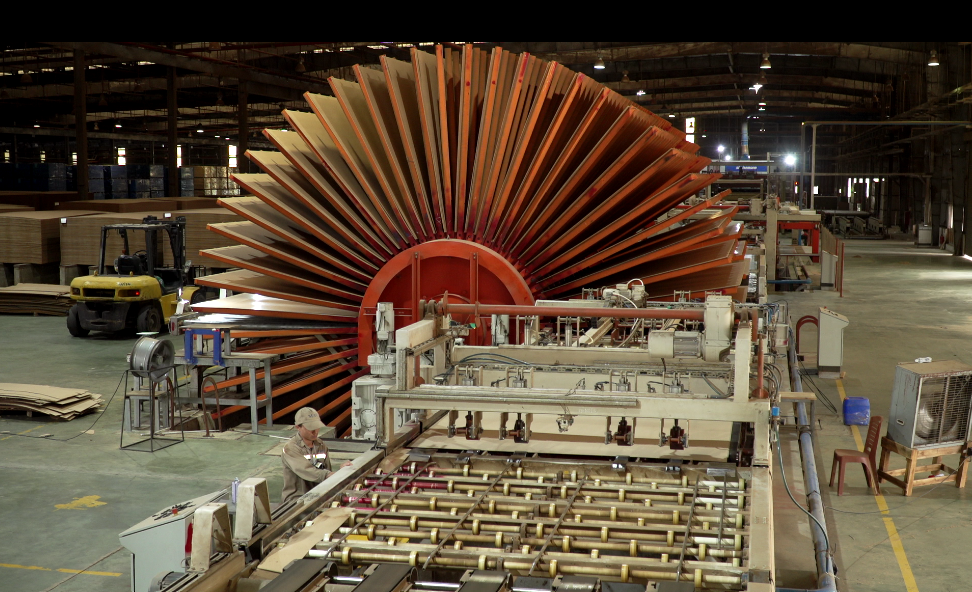

MDF Fiberboard Production Line.

According to Mr. Nguyen The Mai, General Director of Thang Nam Forestry Joint Stock Company, wood processing is a relatively energy-intensive industry. Each year, the company consumes about 35 million kWh of electricity to power machinery and 20,000 tons of fuel to operate thermal boilers, which provide heat and steam for production activities.

Recognizing that energy accounts for a significant portion of product costs, energy saving has always been a top priority for Thang Nam Forestry Joint Stock Company. The company has actively researched solutions to maximize energy savings.

Mr. Nguyen The Mai – General Director of Thang Nam Forestry Joint Stock Company.

Mr. Mai shared that previously, the electricity consumption per unit of product was 300 kWh, resulting in relatively high costs. To address this, the company implemented the following measures: Increased production line capacity to 120-130%; Reduced defective products from 3% to 0.3%; Replaced old motors with new ones equipped with inverters, reducing electricity costs by 15-20%. "These combined solutions have helped the company lower electricity consumption from 300 kWh per unit to approximately 250 kWh per unit," Mr. Mai added.

Regarding the boiler system supplying heat and steam for production, the company has transitioned from using coal and wood chips to using forest by-products (bark) and by-products from wood processing plants. This shift has eliminated the use of fossil fuels and reduced energy costs by 50%.

Inverter-equipped devices help save 15-20% on electricity costs.

In addition to technological solutions, the company has strictly complied with the regulations of the Law on Economical and Efficient Use of Energy. Specifically, the company has established an Energy Management Board, defining the specific roles and responsibilities of each member, and has developed and issued energy usage policies. The Energy Management Board meets weekly to propose initiatives and solutions for better energy savings.

Furthermore, members of the Energy Management Board are prioritized for training and acquiring knowledge on energy-efficient use. This knowledge is then disseminated and applied among the company's employees.

Control room for equipment monitoring and management.

Discussing future energy-saving solutions, Mr. Mai stated that the company is participating in the Voluntary Agreement Program to promote energy efficiency in the industrial sector (VAS) under the Vietnam-Denmark Energy Partnership Program for the period 2020-2025. The aim is to improve energy efficiency within the company.

Through surveys and direct consultations, the company has received valuable input and advice from domestic and international experts to identify energy-saving potentials and technical support during production to enhance energy efficiency.

"As part of the VAS Program, experts have proposed four energy-saving solutions for the company. Among these, the solution to recover excess heat currently being lost to the environment and reuse it in production is considered highly effective in saving energy. If successful, this solution could save the company 4-5 billion VND annually in energy costs," Mr. Mai noted.

According to research conducted by the Vietnam Chamber of Commerce and Industry (VCCI) and the World Wildlife Fund (WWF) in Vietnam, the wood processing industry could reduce energy demand by 10.4% compared to the conventional development scenario if effective and efficient energy-saving measures are implemented.

Duc Do

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Energy-saving solutions and green transition promotion

Energy-saving solutions and green transition promotion

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition