Goshi - Thang Long Motorcycle and Automobile Parts Co., Ltd., established in November 1997, specializes in manufacturing and supplying motorcycle and automobile parts and accessories for Honda Vietnam, Yamaha, Panoma, as well as several other companies, and exports to overseas markets.

Continuous technological improvements for energy efficiency.

According to Mr. Nguyen Minh Tuan, Manager of the Technical Department, efficient and economical use of energy has always been a key focus of the company’s leadership.

To save energy, the company has implemented a number of high-impact measures, including: Replacing the old air compressor with a new model equipped with an inverter; Adding a head guard on the K89 paint jig to reduce conveyor operation time; Reducing electricity consumption for the chillers of plating lines 1 and 2; Replacing the cooling tower water pump in Workshop A; Replacing and upgrading old fans; Automatically shutting off oil pumps to reduce electricity costs for hydraulic pump-operated machines; Switching off electrical cabinet cooling units during non-working days; Using a bypass pipeline to supply clean water directly to Workshop D to reduce electricity costs for water pumps; Adjusting boiler shutdown times to reduce DC electricity costs in plating line 1, etc.

"During inspection and evaluation of the air compressor system, we found that compressors No. 1, 2, 3, and 4 had been in operation since 1997 and had exceeded their depreciation period. Due to prolonged use, their efficiency was low, causing energy waste. Therefore, the company replaced them with new compressors integrated with inverters to improve performance and reduce energy consumption," Mr. Tuan explained.

Energy-saving through inverter-based air compressors.

In addition, to minimize energy loss, the company strictly monitors and repairs compressed air leaks. In 2023 alone, the company repaired 328 leak points, saving 48,544 kWh/year, equivalent to over VND 90 million in cost savings.

The lighting system throughout the production lines, high-bay factory lighting, and perimeter security lighting has been fully converted to LED.

Rooftop solar power system at Workshop D.

Since October 2024, the company has operated a rooftop solar power system at Workshop D with an installed capacity of 550 kWp. On average, the system supplies 59,937 kWh/month, saving the company over VND 122 million per month.

Alongside R&D and the application of scientific and technological solutions, following the Law on Using Energy Efficiency and Conservation and relevant decrees and circulars, the company has: Established an Energy Management Board; Conducted energy audits every three years; Developed annual and 5-year energy efficiency plans; Implemented energy-saving measures across operations.

According to Mr. Tuan, the Energy Management Board is responsible for managing, guiding, analyzing, and evaluating the company’s energy use, proposing solutions to improve efficiency, reduce production costs, and lower CO₂ emissions. It also develops and implements awareness campaigns to encourage all employees to participate in energy-saving activities.

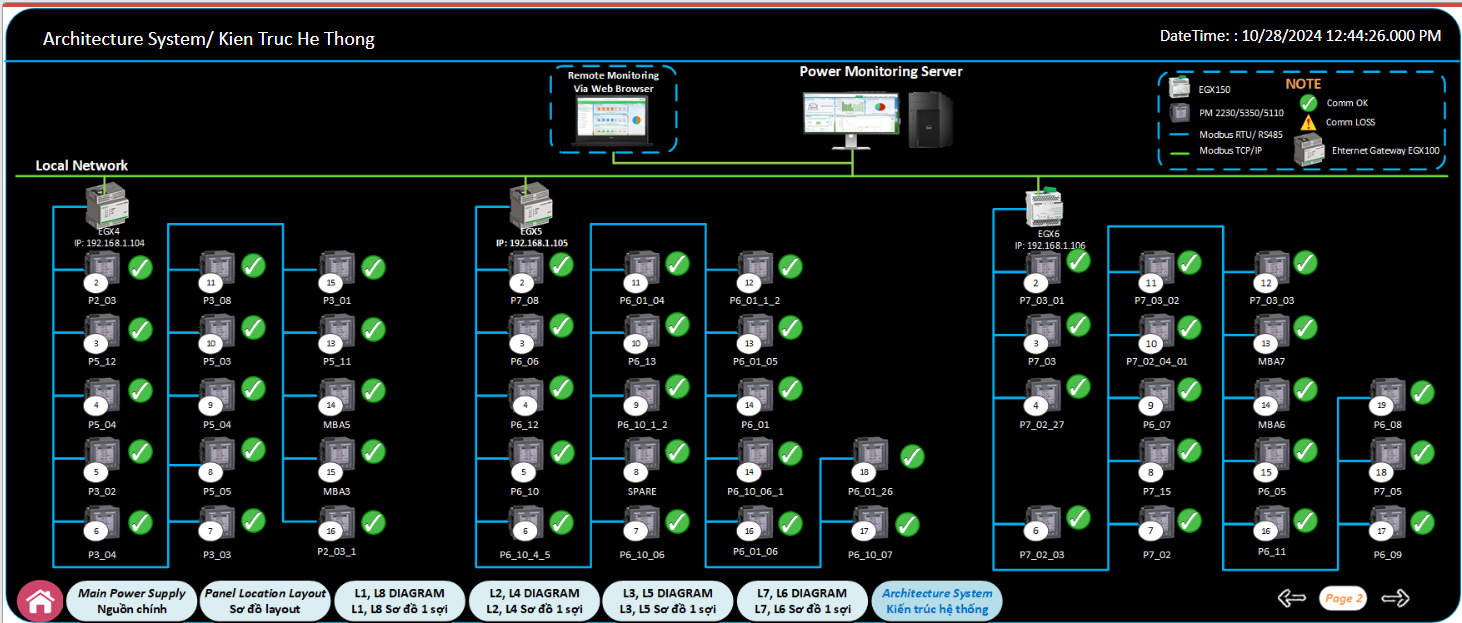

Smart monitoring software.

Notably, the company also uses smart electrical monitoring software capable of collecting data, analyzing reports, and controlling electricity consumption for each department’s electrical equipment. This allows timely planning for process improvements and optimization of energy use for machinery and equipment.

By investing in technological upgrades and integrating a range of energy-saving solutions, Goshi-Thang Long Motorcycle and Automobile Parts Co., Ltd. has significantly reduced its energy consumption, contributing to CO₂ emissions reduction and supporting climate change mitigation efforts.

DUC DO