With the motto “Protecting the global environment through the efficient and economical use of limited resources and energy,” TOTO Vietnam Co., Ltd. has implemented numerous solutions to improve the efficiency of energy use, saving the company billions of VND each year.

TOTO Vietnam Co., Ltd. is a member of the TOTO Group — one of the world’s leading manufacturers of premium sanitary ware. TOTO’s core business focuses on providing bathroom and sanitary equipment products with a wide range of unique styles suitable for households, hotels, high-end apartments, and office buildings. In 2024, TOTO Vietnam was honored with First Prize in the Industrial Energy Efficiency Awards by the Ministry of Industry and Trade and the Science Association. |

According to Mr. Nguyen Trung Kien – Deputy General Manager of Production Engineering at TOTO Vietnam: As a key energy-consuming enterprise, alongside economic development, TOTO Vietnam bears the responsibility of using energy efficiently and economically. Acknowledging this responsibility, in 2013, the company established an Energy Management Board composed of leaders from all departments and units specializing in energy management.

The Energy Management Board advises the Board of Directors on developing policies, mechanisms, and annual and five-year plans for efficient energy use. The board continuously monitors and inspects energy indicators to detect wasteful areas and promptly implements measures to reduce energy consumption through process improvements.

Mr. Nguyen Trung Kien – Deputy General Manager of Production Engineering at TOTO Vietnam.

Alongside energy management, the company has also invested in a series of technological innovations to save energy. These include using solar water heaters for the thermal shock process, replacing 18W LED bulbs with 12W LEDs, improving kiln blower systems, and reducing the drying time in novo keramdry kilns.

The company also uses a large number of localized air conditioners, which operate continuously during peak demand. To enhance cooling efficiency, prolong equipment lifespan, and reduce energy consumption, the company installed Reidan-kun panels for localized air conditioners, saving 74,410 kWh/year — equivalent to 122 million VND.

Furthermore, realizing that its existing chiller system consumed excessive electricity due to the end of its depreciation period, the company decided to replace it with high-efficiency, energy-saving chillers.

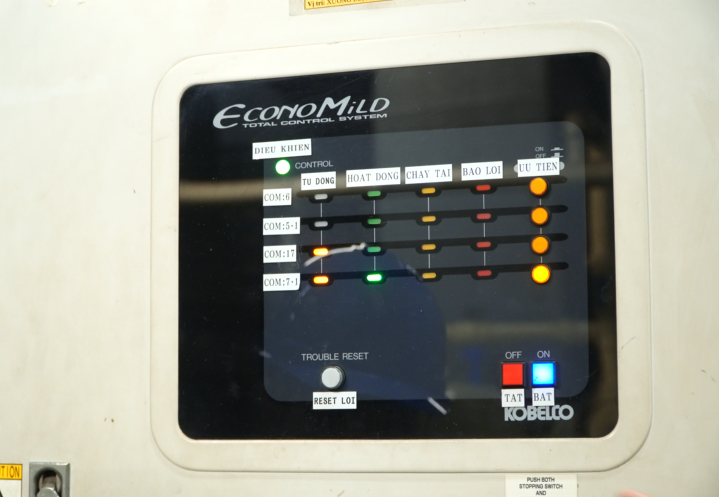

Smart automatic control system Economild for air compressors.

The company also installed inverters and adopted the smart automatic control system Economild for air compressors. Previously, all compressors would start up simultaneously. With Economild, each compressor only operates as needed, based on load requirements (unnecessary compressors are not activated). Automatic operation and regular inspection of air leakages help the company save significantly.

In addition to electricity savings, the company has also invested in gas energy-saving solutions. It installed heat recovery pipelines to capture excess heat from production lines and kilns for reuse in other product drying processes. The company also reduced the weight of kiln support trays and optimized the main kiln temperature to lower gas consumption.

By simultaneously implementing a wide range of energy-saving solutions, TOTO Vietnam Co., Ltd. has reduced electricity consumption from 25.8 million kWh (in 2020) to 13.5 million kWh (in 2023), and LPG consumption from 6.4 million kg (in 2020) to 3.5 million kg (in 2023).

Sharing plans for upcoming energy-saving initiatives, Mr. Nguyen Trung Kien stated: “In 2025, the company will install a solar power system, and by 2027, it plans to switch from LPG to cleaner LNG.”

In the context of rising energy prices, the energy-saving initiatives of TOTO Vietnam Co., Ltd. have proven highly effective, enabling the company to maintain stable production during challenging times.

Duc Do