Steel production emissions are mostly due to traditional blast furnaces, but as the industry responds to the need for cleaner operation, alternatives are increasing in popularity. The simplest way to produce steel from high quality scrap is to melt the ferrous scrap in an electric arc furnace (EAF). With many countries restricting and controlling the construction of traditional blast furnaces, EAF is also a lower cost approach. Furthermore, if the electricity in an EAF is generated from a low carbon source, this is also a more environmentally friendly approach.

There has been a significant adoption of EAFs over the years, and more are being built to replace traditional blast furnaces. In countries where electricity is relatively low cost (and also in Europe), steel produced using electricity already accounts for around 50% of total crude steel production.

In recent decades, the increase in crude steel production has led to a rise in the amount of scrap steel globally. However, good quality steel can be produced from high quality scrap.

According to the Power Quality blog2, the melting point of scrap steel is 1520C, requiring a minimum energy of 300 kWh per ton, although an EAF typically requires 440 kWh per ton of steel. Therefore, significant amounts of electrical energy need to be delivered and reliably controlled for the duration of manufacturing steel.

The best solution is based on silicon-controlled rectifier (SCR) power controllers as, when compared to technologies such as IGBTs, SCRs provide significantly better efficiency - approaching 99.5%. At the power levels seen in an EAF, it is important to eliminate losses wherever possible.

Advanced Energy’s Thyro-PX® digital thyristor SCR power controller

Advanced Energy’s Thyro-PX® digital thyristor SCR power controllers are a modular solution for providing power for the heating elements within an EAF (and many other applications). Scalability is offered through a wide range of single-, dual- and three-phase off-the-shelf solutions. Given the need for stability and repeatability within steel manufacturing, Thyro-PX units are highly accurate (±0.5% voltage or current, ±1.0% power). Individual units can provide up to 5000 A of current from a line voltage up to 1000 V.

Often there is a need to independently control several single-phase loads within an application. Thyro-PX controllers address this with a sophisticated multi-zone capability.

The controllers are intended for use with sophisticated control systems. To facilitate this, an Anybus® Digital Interface Card provides connectivity to many popular protocols including Ethernet / IP, EtherCAT, PROFIBUS, PROFINET, Modbus TCP/IP and DeviceNET. For localized control, a Thyro-Touch 2.8” display can be integrated to the main unit as an option. As well as permitting intuitive operation, the display contains a process data recorder for up to six process parameters as well as status messages.

Thyro-PX controllers operate in Full Wave (TAKT) mode, which makes synchronizing multiple units simple and reduces wattless power. The TAKT scheme also removes harmonic components and DC content. Perhaps the greatest benefit of TAKT is that it allows for mains load optimization, overcoming any effects of simultaneously grid connecting several power controllers. The control algorithms within Advanced Energy’s SCR controllers also significantly reduce peak loads on the mains, while considering any effects of setpoint and load changes.

Higher Voltages

The power requirements of EAFs imply very high currents, which require thick bus bars and heavy cabling. This is expensive and can be challenging from an installation perspective.

To address this, Advanced Energy has developed a multi-phase, air-cooled Thyro-PX unit with an output voltage of 1000 V and a 900 A current capability. The resulting lower current reduces I2R losses in cables and bus bars. This permits the use of bus bars and cables that are thinner and lighter, which eases installation and reduces both installation and operating costs.

Stacking for Higher Current Applications

Some metal-related applications will require even higher current ranges. The Thyro-PX platform can accommodate these higher levels through its ability to operate thyristors in a parallel, water-cooled stack configuration.

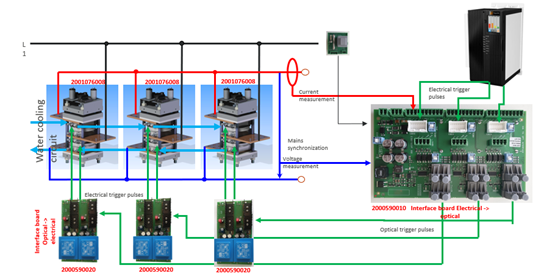

The above figure shows configuration example that separates the control section from the power section to use the Thyro-PX in higher voltage applications.

SCR system components for stacked configuration

These stacks, which comprise multiple thyristor disc cells of different sizes based on application, support DC and both single-phase and three-phase AC designs and take full advantage of the existing Thyro-PX card architecture for precise and accurate control and advanced communications. With the advantage to separate control section from power section via fiber optic Thyristor signaling, EMC problems can be avoided. The Thyro-PX Modular allows high currents up to 12 kA at 690 V.

According to advancedenergy.com

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Energy-saving solutions and green transition promotion

Energy-saving solutions and green transition promotion

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition