Thursday, 05/02/2026 | 01:07 GMT+7

First, understand where your business is using the most energy, so you can find ways to reduce and save.

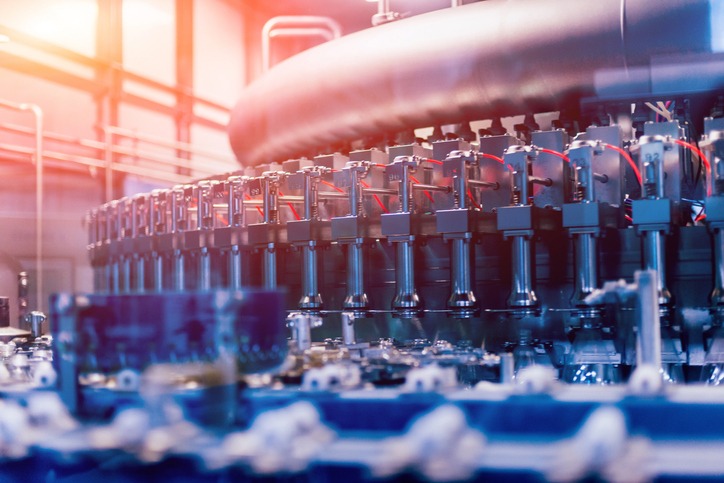

Based on the business’ we’ve worked with in the food and beverage manufacturing industry, the most common areas that use the most energy are:

Buy and set up a gas or electricity meter on equipment that uses the most energy to monitor use.

The meter can show you how much energy the equipment uses and when. This data can be analysed to see if it’s working efficiently. You may find you can downsize equipment or discover when it needs maintenance.

On average, food and beverage manufacturing businesses installing meters on high-energy equipment found they:

Heat recovery is a process where you redirect and use heat that would otherwise be vented outside.

You can use the recovered heat to preheat water for boilers or heat the workplace.

On average, food and beverage manufacturing businesses investing in heat recovery found they:

Some of your equipment may be running when it doesn’t need to be.

Add timers and operational controls to equipment that can be switched off overnight or when it’s not being used. This can take the effort out of training staff to manually switch equipment off.

Use timers to switch off equipment like:

On average, food and beverage manufacturing businesses adding timers and operational controls to high-energy equipment found they:

Insulating steam or chilled water piping will reduce heat losses and improve productivity.

On average, food and beverage manufacturing businesses insulating piping found they:

A variable speed drive controls the speed and frequency of a motor to match demand. If your process demand varies, you’ll reduce energy use and cost by installing a variable speed drive to:

On average, food and beverage manufacturing businesses installing variable speed drives found they:

Apart from making sure you’re using the appropriate air pressure, you can also prevent wasting energy by regularly maintaining your compressed air systems, looking for:

On average, food and beverage manufacturing businesses maintaining compressed air systems found they:

You can switch to renewable energy by:

On average, food and beverage manufacturing businesses that invest in renewable energy found they:

Energy Efficiency and Conservation: Technology as the “Key”

Energy Efficiency and Conservation: Technology as the “Key”

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Opening of the 2025 Energy-Efficient Equipment and Green Transition Exhibition Fair

Energy-saving solutions and green transition promotion

Energy-saving solutions and green transition promotion

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Consultation on the methodology for developing and updating energy consumption standards for four major industrial sectors

Develop sales and marketing strategies for energy efficiency equipment and solution suppliers

Develop sales and marketing strategies for energy efficiency equipment and solution suppliers

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition

The 9th VEPG Steering Committee Meeting: Strengthening Coordination for Viet Nam’s Just Energy Transition